山东清越科技有限公司

Shandong clear energy technology Co. Ltd.

国内设备

设备,拥有多项

全国服务热线:

0531-55555478

山东空压机的选型要求有哪些?

空压机选型对用户本身和空压机设备都关重要,选型过大太过浪费,选型过小可能造成空压机长期处于加载状态或用气不够或压力打不上去等弊端。

The selection of air compressor is very important to the user and the air compressor equipment. Too large selection is too wasteful. Too small selection may cause the air compressor to be in the loading state for a long time or the air is not enough or the pressure can not be increased.

空压机选型一般遵循的步骤是:先确定工作压力,再定相应容积流量,是供电容量。 空压机选型一步:确定工作压力 空压机选型时,要确定用气端所需要的工作压力,加上1-2 bar的余量,再选择空压机的压力。

Air compressor selection generally follow the steps: first determine the working pressure, and then determine the corresponding volume flow, is the power supply capacity. One step of air compressor selection: determine the working pressure. When selecting the air compressor, first determine the working pressure required by the air end, add the margin of 1-2 bar, and then select the pressure of the air compressor.

山东空压机

Shandong air compressor

当然,管路通径的大小和转弯点的多少也是影响压力损失的因素,管路通径越大且转弯点越少,则压力损失越小;反之,则压力损失就越大。 因此,当空压机与各用气端管路之间距离太远时,应适当放大主管路的通径。如果环境条件符合空压机的安装要求且工况允许的话,可在用气端就近安装。

Of course, the size of the pipeline diameter and the number of turning points are also factors that affect the pressure loss. The larger the pipeline diameter and the less the turning points, the smaller the pressure loss; on the contrary, the greater the pressure loss. Therefore, when the distance between the air compressor and the gas end pipeline is too far, the diameter of the main pipe should be appropriately enlarged. If the environmental conditions meet the installation requirements of the air compressor and the working conditions permit, it can be installed near the gas end.

空压机选型二步:确定相应容积流量 1、空压机选型时,应先了解所有的用气设备的容积流量,把流量的总数乘以1.2; 2、向用气设备供应商了解用气设备的容积流量参数进行空压机选型; 3、空压机站改造可参考原来参数值结合实际用气情况进行选型

Two steps of air compressor selection: determine the corresponding volume flow. 1. When selecting the air compressor, you should first understand the volume flow of all the gas equipment, and multiply the total flow by 1.2. 2. Learn the volume flow parameters of the gas equipment from the gas equipment supplier, and then select the air compressor. 3. The transformation of the air compressor station can refer to the original parameters combined with the actual gas consumption

空压机选型三步:确定供电容量 在功率不变的情况下,当转速发生变化时,容积流量和工作压力也相应发生变化,转速降低了,排气也相应减少了,依此类推。 空压机选型功率是在满足工作压力和容积流量的条件下,供电容量能满足所匹配驱动电机的使用功率即可

Three steps of air compressor selection: determine the power supply capacity. Under the condition of constant power, when the speed changes, the volume flow and working pressure also change accordingly, the speed decreases, the exhaust also decreases, and so on. Air compressor power selection is to meet the working pressure and volume flow conditions, the power supply capacity can meet the power of the matching drive motor

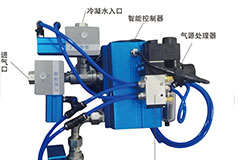

上一篇:制氮系统的冷干机室外使用注意事项

下一篇:如何拆卸空压机的减荷阀?

鲁公网安备 37010402001146号

鲁公网安备 37010402001146号