山东清越科技有限公司

Shandong clear energy technology Co. Ltd.

国内设备

设备,拥有多项

全国服务热线:

0531-55555478

影响干燥机效果的因素及设备特点

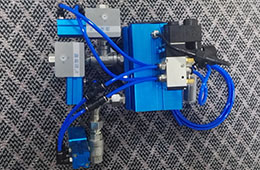

干燥机由主机、空气处理系统、加热系统、控制系统等组成。工作时,物料加入干燥机的料斗,按工艺要求设定程序和参数,整机开始工作。空气经过空气处理系统过滤、经加热系统加热后进入主机,物料经热空气流化,水份迅速蒸发,物料被快速干燥。

The dryer is composed of main machine, air handling system, heating system and control system. When working, the material is added into the hopper of the dryer, the program and parameters are set according to the process requirements, and the whole machine starts to work. The air is filtered by the air treatment system and heated by the heating system before entering the main engine. The material is fluidized by hot air, and the water evaporates rapidly, and the material is dried rapidly.

按设定的程序与参数完成操作后,将料仓推出与提升转料机扣合提升出料,有效地控制粉尘与交叉污染。设备处于密闭负压下工作,且整个设备内表面光洁,无死角,易于清洗,符合“GMP”要求。

After the operation is completed according to the set procedures and parameters, the silo is pushed out and connected with the lifting transfer machine to lift the discharge material, so as to effectively control the dust and cross pollution. The equipment works under closed negative pressure, and the inner surface of the whole equipment is smooth and clean without dead angle, which is easy to clean and meets the requirements of GMP.

干燥机能直接将液态物料干燥、具有快速干燥颗粒、粉状物料等多种功能。装物料的料斗是锥形,可增加物料的流速,便于流化,物料在料斗内不易形成死角,物料吸受热量均匀,烘干速度快。装物料的料斗内备有取样装置,可随时取样,以测试物料的干燥的干燥终点,保证产品质量。

The dryer can directly dry liquid materials, and has many functions such as fast drying particles and powder materials. The hopper for loading materials is conical, which can increase the flow rate of materials and facilitate fluidization. The materials are not easy to form a dead angle in the hopper. The materials absorb heat evenly and dry fast. A sampling device is equipped in the hopper for loading materials, which can sample at any time to test the drying end point of materials and ensure the quality of products.

干燥机有冷风后处理工艺,干燥后的物料可及时通冷风冷切。可防止物料因余热过度而变质,确保了物料烘干质量。采用特殊材料进行空气热过滤,以防散热器的异物及空气中的杂质进入物料,确保物料的干净纯洁。沸腾干燥机设计了特殊的气体分布板,使载热气流横向呈螺旋状进入,使沸腾起的物料流分接触载热气流,吸受热量均匀,物料干燥快。减少了蒸汽消耗,节约了能源。

the dryer has cold air post-treatment process, and the dried materials can be cut by cold air in time. It can prevent materials from deteriorating due to excessive waste heat and ensure the drying quality of materials. Special materials are used for air thermal filtration to prevent foreign matters in the radiator and impurities in the air from entering the materials and ensure the cleanliness of the materials. A special gas distribution plate is designed in the boiling dryer to make the heat carrying gas flow enter into the dryer in a transverse spiral shape, so that the boiling material flow contacts the heat carrying gas flow separately, and the heat absorption is uniform, and the material drying is fast. The steam consumption is reduced and the energy is saved.

一般来说,影响干燥效果的四个因素,即干燥温度,露点,时间和气流。

generally speaking, there are four factors affecting the drying effect, namely drying temperature, dew point, time and air flow.

干燥机的干燥温度也是一个重要因素。热量是打开聚合物之间的水分和水分的关键。当高于一定温度时,水分子和聚合物链会大大降低重力,水蒸气会被干燥的空气吹走。因此,干燥温度对终干燥效果的影响也有重要的影响。

The drying temperature of the dryer is also an important factor. Heat is the key to opening the water and moisture between polymers. Above a certain temperature, water molecules and polymer chains will greatly reduce the gravity, and water vapor will be blown away by dry air. Therefore, the drying temperature also has an important influence on the final drying effect.

上一篇:空压机后处理设备如何保障设备品质的?

下一篇:空压机维修中缩短检修时间的技术方法

鲁公网安备 37010402001146号

鲁公网安备 37010402001146号