山东清越科技有限公司

Shandong clear energy technology Co. Ltd.

国内设备

设备,拥有多项

全国服务热线:

0531-55555478

CLEAR ENERGY

螺杆鼓风机润滑脂如何更换?

来源:https://www.sdqyjn.com/ 日期:2021-06-28 浏览量:0

TAG:山东制氮机,山东干燥机,山东螺杆鼓风机,山东空压机,山东自动排水器

螺杆鼓风机润滑脂经过一段时间的使用,会发生性能老化和泄露消耗,因此需要及时进行补充或更换。罗茨鼓风机使用润滑脂,通常每3个月左右补充一次,是否需要更换,应视润滑脂的质量状况而定。主要判断依据:

After a period of use, the grease of screw blower will have performance aging and leakage consumption, so it needs to be supplemented or replaced in time. Roots blower uses grease, which is usually replenished every three months. Whether it needs to be replaced depends on the quality of grease. Main judgment basis:

(1)检验螺杆鼓风机是否混用太多的硬粒杂志。检验时,用手指取少量润滑脂进行捻压,凭感觉可以判断;

(1) Check the screw blower for mixing too many hard particles. During inspection, take a small amount of grease with your fingers for twisting and pressing, which can be judged by feeling;

(2)检验螺杆鼓风机是否氧化变质。如果已经氧化变质,从外观上就可分辨得出。这时润滑脂的颜色变黑或者加深,并且表面会形成较硬的胶膜。

(2) Inspect the screw blower for oxidation and deterioration. If it has been oxidized, it can be distinguished from the appearance. At this time, the color of the grease becomes black or deepened, and a hard film will form on the surface.

(3)不同种类的脂不能混合,新脂、旧脂不能混合,因此更换润滑脂时,应将废脂彻底,然后填入新脂。

(3) Different kinds of grease can't be mixed, new grease and old grease can't be mixed, so when changing grease, the waste grease should be completely removed, and then filled with new grease.

(4)润滑脂的填充应当适量。填充过少,会造成润滑不够。填充过量,润滑脂过度搅拌、急剧升温,又造成分油、分解与泄露。

(4) The filling of lubricating grease should be appropriate. Too little filling will result in insufficient lubrication. Overfilling, excessive stirring and sharp temperature rise of grease cause oil separation, decomposition and leakage.

螺杆鼓风机的润滑脂要及时的补充和更换,保证螺杆鼓风机的正常使用。想要了解更多精彩内容可以直接点击:https://www.sdqyjn.com会定期呈现内容。

The grease of screw blower should be supplemented and replaced in time to ensure the normal use of screw blower. If you want to know more, you can click: https://www.sdqyjn.com Content is presented on a regular basis.s.

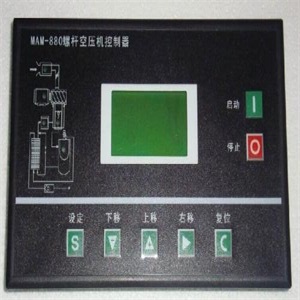

上一篇:空压机频繁加卸载原因及故障分析

下一篇:空压机频繁加卸载原因及故障分析

相关新闻

鲁公网安备 37010402001146号

鲁公网安备 37010402001146号