山东清越节能科技有限公司

Shandong clear energy technology Co. Ltd.

国内环保设备品牌

节能设备专家,拥有多项国家专利

全国服务热线:

0531-55555478

如何预防空压机油分芯烧毁?

油分芯是螺杆空压机重要的配件之一,是把油和气分离开,让油回到空压机内部循环,让气排出供给用户使用。同时,油分芯也是易损的耗材,到期后就需要及时更换。

Oil core separation is one of the important accessories of screw air compressor, which separates oil and gas, so that the oil returns to the internal circulation of the air compressor, so that the gas is discharged for the use of users. At the same time, the oil separation core is also vulnerable consumables, which needs to be replaced in time after expiration.

在使用过程中,会遇到不同的故障问题,油分芯烧毁是其中一种。油分芯烧毁故障实际上是油分芯被点燃了,那么,预防空压机油分芯烧毁的措施是什么?

In the process of use, there will be different fault problems, one of which is burning oil core. Oil core burning fault is actually the oil core is ignited, so, what are the measures to prevent air compressor oil core burning?

1、停用了一段时间的空压机,或冬天气温低时,再次启动机器前,往主机内部加入少量润滑油,让主机启动时有润滑油和冷却。

When the air compressor has been stopped for a period of time, or when the temperature is low in winter, before starting the machine again, add a small amount of lubricating oil to the main engine, so that there is lubricating oil and cooling when the main engine starts.

2、日常运行中,注意空压机的排气温度,一旦发现机器长时间排气温度过高运行时,找出高温的原因并解决问题。让空压机在正常的排气温度

2. In daily operation, pay attention to the exhaust temperature of the air compressor. Once it is found that the exhaust temperature of the machine is too high for a long time, find out the cause of high temperature and solve the problem. Let the air compressor at normal exhaust temperature

下运行,避免机器长时间的高温,引发油路系统故障从而导致火灾的发生。

To avoid long-term high temperature of the machine, which will cause oil system failure and cause fire.

3、静电释放明火烧毁油分芯。检测空压机的接地是否正常、油气桶是否与机器地线导通、安装油分时注意观察与石棉垫接触的油气桶平面是否有异物。例如生锈的平面、有涂过密封胶的平面,或者其他异物影响到与油分接地导通。

3. Electrostatic discharge and open fire destroy the oil core. Check whether the grounding of the air compressor is normal, whether the oil and gas drum is connected with the ground wire of the machine, and pay attention to observe whether there are foreign matters on the plane of the oil and gas drum contacting with the asbestos pad when installing the oil separator. For example, rusty surface, coated with sealant plane, or other foreign matters affect the connection with oil sub grounding.

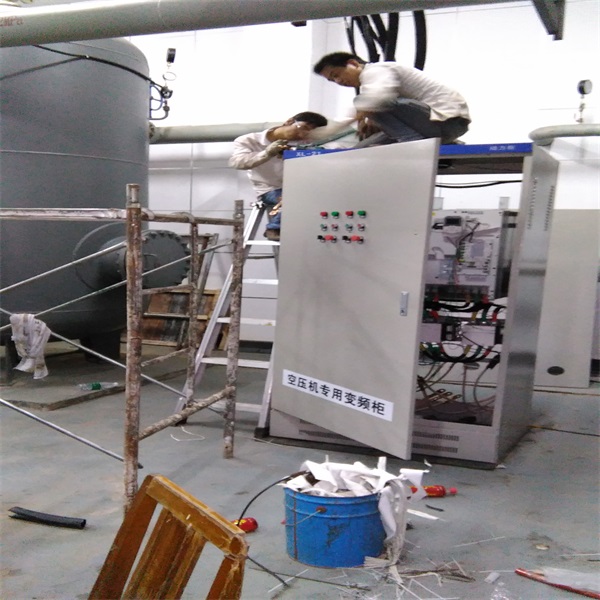

4、检查电控箱内有无纤维、泡沫或者其他易燃的材料,防止电控箱内各部件工作时产生的电弧引燃这些材料,从而引发火灾烧毁机器。

4, check whether there is any fiber, foam or other inflammable materials in the electric control box, prevent the electric arc generated by the components in the electronic control box to ignite these materials, thus causing the fire to burn down the machine.

5、设计了温控阀的空压机出现高温问题,应遵循根治问题的原则。温控阀坏了该更换就更换,不要随意短接温控阀。

5. The air compressor designed with temperature control valve has high temperature problem, which should follow the principle of radical cure. If the temperature control valve is broken, it should be replaced. Do not short circuit the temperature control valve at will.

6、喷油回转空压机由于排气温度低,一般没有积碳的问题,但作为循环油,应具有良好的抗氧化作用,以保证一定的寿命。对于喷油回转式空压机应该使用特殊油,或具有良好抗乳化的循环油。抗氧化剂在一般的压缩机温度下应具有足够低的挥发性,使润滑油保持到换油时间。

6. Because of the low exhaust temperature of oil injection rotary air compressor, generally there is no carbon deposition problem, but as a circulating oil, it should have good oxidation resistance to ensure a certain life. For oil injection rotary air compressor, special oil or circulating oil with good demulsification resistance should be used. Antioxidants should have enough low volatility at general compressor temperature to keep lubricating oil to oil change time.

上一篇:制氮机如何正确保养才能延长使用寿命

下一篇:山东空压机的组成结构

鲁公网安备 37010402001146号

鲁公网安备 37010402001146号