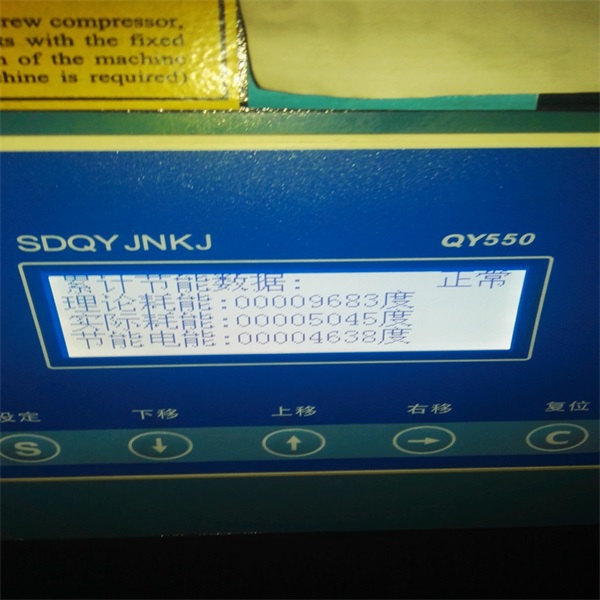

山东清越节能科技有限公司

Shandong clear energy technology Co. Ltd.

国内环保设备品牌

节能设备专家,拥有多项国家专利

全国服务热线:

0531-55555478

选择空气机要求的规格和要求有哪些?

选择空气机要求的规格和要求,如空气质量,温度,电源,规模和流动性的认识。一些空气压机都配备电机(螺杆式压缩机),取出的凝结,这是在压缩过程中中创建的。其他包括冷却器,降低压缩空气的温度。纸或聚酯过滤器,清除油污,灰尘,蒸气,及其他杂物的空气压缩机也可,无油空气是特别重要的应用,如食品加工和半导体制造,部分低至每十亿(PPB油)是不可接受的。规模较小的空气压缩机通常由汽油,柴油燃料,或单相电力供电。在流动性方面,在208V,230V或460V。较大,商业及工业单位经常使用三相电源的便携式空气压缩机功能轮,脚轮,或自足的拖车。立式空气压缩机是专为固定安装,需要更少的地面空间。

Select the specifications and requirements of the air machine requirements, such as air quality, temperature, power supply, scale and liquidity awareness. Some air compressors are equipped with motors (screw compressors) to remove the condensation, which is created during the compression process. Others include coolers to lower the temperature of the compressed air. Paper or polyester filters, air compressors that remove oil, dust, vapor, and other debris are also acceptable. Oil free air is particularly important for applications such as food processing and semiconductor manufacturing, and parts as low as 1 billion (ppb oil) are not acceptable. Smaller air compressors are usually powered by gasoline, diesel fuel, or single-phase electricity. In terms of liquidity, at 208v, 230V or 460V. Large, commercial and industrial units often use three-phase power for portable air compressors, functional wheels, casters, or self-contained trailers. The vertical air compressor is designed for fixed installation and requires less ground space.

空气机,压缩和直接用于工业应用的空气。小规模设备的设计气动工具,如磨床,钻头,射钉枪。生产规模的产品是用来驱动冲压和冲压设备,电力机械手工具,并转达部分。也可直接使用的应用程序,如喷砂和喷漆设计的空气压缩机。有三种基本类型的空气压缩机:往复式压缩机,旋转螺杆式压缩机和离心压缩机。往复式空气压缩机用活塞压缩气缸的内容,并迫使他们进入储气罐。这些活塞驱动的空气压缩机是专为间歇性使用。螺杆空压机使用双螺杆活塞加压空气。他们是专为连续使用,并有100%的额定占空比。离心式空气压缩机是旋转的叶片,以产生高压力使用的涡轮发动机。通常情况下,这些空气压缩机用于发电和大规模的工业应用。

Air compressor, which compresses and directly uses air for industrial applications. Small scale equipment design pneumatic tools, such as grinder, drill bit, nail gun. Production scale products are used to drive stamping and stamping equipment, power manipulator tools, and transfer parts. It can also be used directly for applications such as sandblasting and spray painting design of air compressors. There are three basic types of Air Compressors: reciprocating compressors, rotary screw compressors and centrifugal compressors. Reciprocating air compressors use pistons to compress the contents of cylinders and force them into the reservoir. These piston driven air compressors are designed for intermittent use. Screw air compressor uses twin-screw piston to pressurize air. They are designed for continuous use and have a 100% rated duty cycle. Centrifugal air compressors are rotating blades to produce high pressure for use in turbine engines. Typically, these air compressors are used for power generation and large-scale industrial applications.

空气压缩机压力,空气流量,效率和经营成本的重要参数。空气压力通常是在每平方英寸(psi)磅来衡量。通常是衡量标准立方米每分钟英尺(SCFM)的空气流量。往复式空气压缩机可以实现高达100CFM空气流动。回转式空气压缩机能达到1500单级CFM和高达2500CFM两个阶段。离心式空气压缩机操作水平超过1000CFM。关于空气压缩机的效率,压缩空气和气体研究所(CAGI)已开发出一套标准的测试标准。空气压缩机的供应商可以提供有关马力,效率和预期的能源消耗的信息CAGI数据表。

Air compressor pressure, air flow, efficiency and operating costs are important parameters. Air pressure is usually measured in pounds per square inch (PSI). It is usually a measure of air flow in standard cubic meters per minute (scfm). Reciprocating air compressor can achieve up to 100 CFM air flow. Rotary air compressor can reach 1500 single stage CFM and 2500 CFM. The operating level of centrifugal air compressor exceeds 1000CFM. Regarding the efficiency of air compressors, the compressed air and Gas Institute (cagi) has developed a set of standard test standards. The supplier of the air compressor can provide information on horsepower, efficiency and expected energy consumption in cagi data sheet.

相关标签:山东空压机

上一篇:山东制氮机常见的故障处理方式

下一篇:为什么说干燥机的水平与科技发展有关呢?

鲁公网安备 37010402001146号

鲁公网安备 37010402001146号