山东清越节能科技有限公司

Shandong clear energy technology Co. Ltd.

国内环保设备品牌

节能设备专家,拥有多项国家专利

全国服务热线:

0531-55555478

空压机主机在维修中零部件操作规范

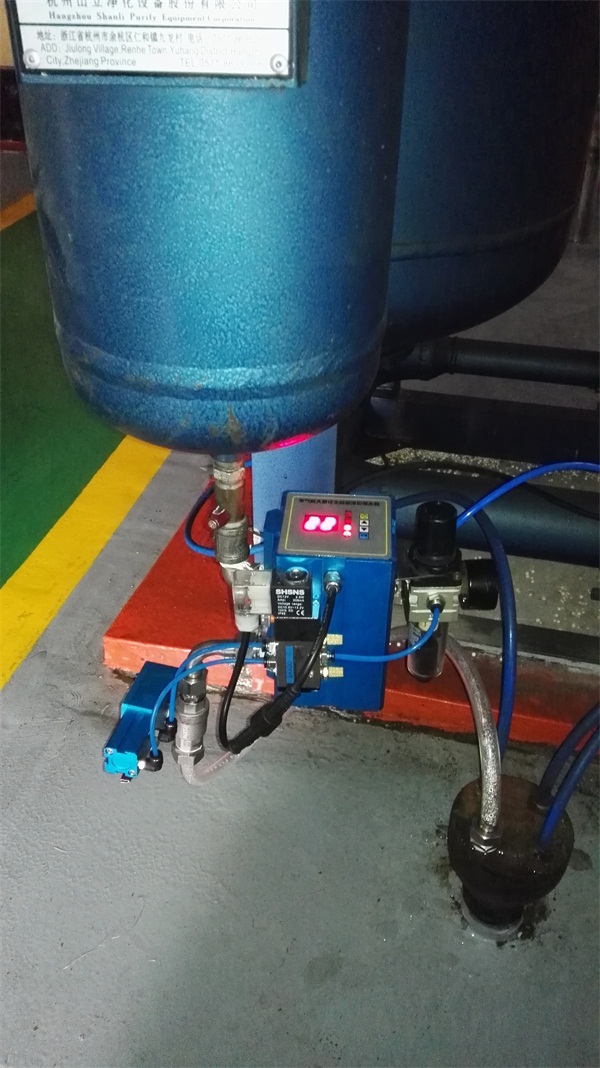

空压机主机维修是针对空压机维修保养中重要的一个环节,更好的保养空压机转子与轴承能更好的维护机器使用年限。当喷油螺杆压缩机使用时间过长,螺杆转子可能会出现以下问题:

The maintenance of air compressor host is the important link in the maintenance of air compressor. Better maintenance of air compressor rotor and bearing can better maintain the service life of the machine. When the oil injection screw compressor is used for a long time, the screw rotor may have the following problems:

关于空压机主机中转子维修的损害

Damage of rotor maintenance in air compressor main engine

1、轴承磨损

1. Bearing wear

2、啮合间隙过大

2. Excessive meshing clearance

3、油路不畅

3. The oil circuit is not smooth

4、振动、运行噪声过大造成问题的原因是因为转子长时间在高负荷及高温度下运行难免将 产生机械磨损和疲劳,如果不进行及时的检查及修理,您将可能面临很多损失:空压机转子磨损;a、转子异常摩擦、窜动 b、运行可靠性下降 c、效率下降,能耗增大 d、突然损坏,彻底影响生产。

4. The reason for the problem caused by excessive vibration and running noise is that the rotor will inevitably suffer from mechanical wear and fatigue if it is operated under high load and high temperature for a long time. If you do not conduct timely inspection and repair, you may face many losses: wear of air compressor rotor; A. abnormal friction and movement of rotor; B. decrease of operation reliability; C. decrease of efficiency and increase of energy consumption d. Sudden damage, completely affecting production.

引起轴承损伤的原因很多,诸如安装不当、污物侵入或水分侵入等是很多轴承早期损伤的常见原因。以下是一些大尺寸轴承的常见损坏原因分析以及相应的能验长轴承寿命的预防措施。

There are many reasons for bearing damage, such as improper installation, dirt intrusion or moisture intrusion. The following is a number of large-scale bearing damage cause analysis and the corresponding can test long bearing life preventive measures.

A、操作不当:安装、操作或拆卸不当可能引起保持架变形或缺损预防措施:使用合适的操作、安装和拆卸工具。

A. Improper operation: improper installation, operation or disassembly may cause deformation or defect of cage preventive measures: use appropriate operation, installation and removal tools.

B、润滑不充分:润滑不充分或不当可能导致元件擦伤或者严重的轴承变形预防措施:改进润滑系统,定时恰当地补充或更换润滑剂。

B. Inadequate lubrication: inadequate or improper lubrication may result in component scuffing or severe bearing deformation. Preventive measures: improve the lubrication system and replenish or replace the lubricant properly at regular intervals.

C、生锈与腐蚀:接触水可能导致轴承元件蚀损并生锈。锈蚀损伤后的轴承在工作时可能导致剥落预防措施:定期检查密封,保证良好的密封效果,正确储存轴承。

C. Rust and corrosion: contact with water may cause corrosion and rust of bearing elements. Preventive measures: regularly check the seal to ensure good sealing effect and store the bearing correctly.

D、电流:轴承转动时通电可能导致出现凹槽或刻痕。轴承静止时,电气操作接地不当会导致轻微的烧伤预防措施:在对轴承以外的部件焊接前通过适涤的连接减少或避免电流通过轴承。

D. Current: energizing the bearing as it rotates may cause grooves or nicks. When the bearing is still, improper grounding of electrical operation may cause slight burn. Preventive measures: reduce or avoid the current passing through the bearing through a suitable polyester connection before welding the parts other than the bearing.

E、外部材料:磨损性颗粒污染和碎片侵入可能导致轴承工作面磨损、擦伤和凹陷预防措施:清楚侵入颗粒和碎片,更换润滑剂,检查密封系统。

E. External materials: abrasive particle contamination and debris intrusion may cause wear, scuffing and dents on the bearing working surface preventive measures: clear the invasive particles and debris, replace the lubricant, and check the sealing system.

F、偏心:偏心、倾斜或过大负荷可能导致几何应力集中或表面剥落预防措施:精确加工轴承座和挡肩。

F. Eccentricity: eccentricity, tilt, or excessive load may cause geometric stress concentration or surface spalling preventive measures: accurately machine the bearing pedestal and shoulder.

标签:山东空压机

上一篇:螺杆鼓风机的工作原理及结构特点

下一篇:冷冻式干燥机与吸附式干燥机的不同之处是什么呢?

鲁公网安备 37010402001146号

鲁公网安备 37010402001146号