山东清越节能科技有限公司

Shandong clear energy technology Co. Ltd.

国内环保设备品牌

节能设备专家,拥有多项国家专利

全国服务热线:

0531-55555478

空压机配件高温故障怎么办

相对于活塞式空压机,空压机的配件较多:传感器、温控阀、过滤器、主控器等等,这也造就了螺杆式空压机相对活塞机结构较复杂,后期的维护保养也就显得重要一些。

Compared with the piston air compressor, the air compressor has more accessories: sensor, temperature control valve, filter, main controller, etc., which also makes the screw type air compressor relatively complex compared with the piston machine, and the later maintenance is also important.

当然面对高温环境,配件的运行状态也就需要注意:空压机配件正常运行的温度在75℃-95℃,当高于这个温度上限时,属于高温。引起高温的原因有许多,分析并判断空压机高温的起因,才是解决高温的前提基础。

Of course, in the face of high temperature environment, the operating state of accessories also needs attention: the normal operation temperature of air compressor accessories is 75 ℃ - 95 ℃. When it is higher than the upper temperature limit, it belongs to high temperature. There are many causes of high temperature. Analyzing and judging the cause of high temperature of air compressor is the premise of solving high temperature.

一:主控器故障。出现乱报警的情况。如果是因为这个原因才出现空压机面板上显示高温。解决方案:更换新的主控器。

1: Master controller failure. There is a random alarm situation. If it is because of this reason that the air compressor panel shows high temperature. Solution: replace the main controller with a new one.

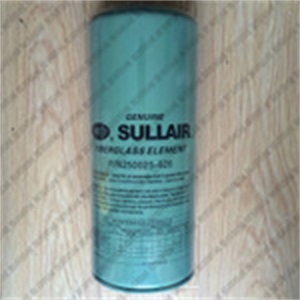

二:油过滤器堵塞。油过滤器的作用是将润滑油中的杂质过滤,保护空压机的主机。如果长时间不更换,或是使用的环境比较恶劣,导致油过滤器堵塞,压缩机内部的油路流量小,主机不能及时的获得足够量的润滑油冷却,会出现高温现象。解决方案:更换油过滤器,或是做一次油路保养。

2: The oil filter is blocked. The function of oil filter is to filter the impurities in lubricating oil and protect the host of air compressor. If the oil filter is not replaced for a long time, or the use environment is relatively bad, resulting in the blockage of the oil filter, the internal oil flow of the compressor is small, and the main engine can not get enough lubricating oil cooling in time, the phenomenon of high temperature will occur. Solution: replace the oil filter, or do a maintenance of the oil circuit.

三:缺少润滑油。空压机的润滑油不仅有润滑、密封作用,它主要的是还可以冷却机组,因而也称作“冷却液”,当机器缺少冷却液时,空气压缩机产生的热得不到冷却,则温度就会越升越高,这也是引起空压机高温的主要因素之一。解决方案:添加空压机油,如果是润滑油油品变质导致的高温,则更换。

3: Lack of lubricating oil. The lubricating oil of air compressor not only has the function of lubrication and sealing, but also can cool the unit, so it is also called "coolant". When the machine is short of coolant, the heat generated by the air compressor can not be cooled, and the temperature will rise higher and higher, which is one of the main factors causing high temperature of air compressor. Solution: add air compressor oil, if it is high temperature caused by deterioration of lubricating oil, replace it.

四;温控阀故障。温控阀的作用是控制空压机主机的喷油温度;它利用温控元件根据油温控制该元件阀芯的开启度,从而控制通过油冷却器的油量,让冷,热油混合后到主机去,从而控制了喷油及排气温度!解决方案:更换温控阀芯。

4、 Temperature control valve failure. The function of the temperature control valve is to control the injection temperature of the air compressor main engine; it uses the temperature control element to control the opening degree of the valve core of the element according to the oil temperature, so as to control the amount of oil through the oil cooler, so as to mix the cold and hot oil to the main engine, so as to control the oil injection and exhaust temperature! Solution: replace the temperature control valve core.

相关标签:山东空压机

上一篇:怎样优化干燥过程中的气流

下一篇:矿用空压机故障原因分析与解决方法

鲁公网安备 37010402001146号

鲁公网安备 37010402001146号