山东清越节能科技有限公司

Shandong clear energy technology Co. Ltd.

国内环保设备品牌

节能设备专家,拥有多项国家专利

全国服务热线:

0531-55555478

空压机后处理设备如何保障设备品质的?

空压机后处理设备除去水份、过滤杂质、清除油雾等洁净压缩空气的关键性设备,是为产品品质与用气设备“保驾护航”的“屏障”,如果这道“屏障”失守,压缩空气将毫无用处,甚至成为“祸害”。那么,压缩空气后处理技术或设备如何才能担当此重任呢?

Air compressor post-treatment equipment is the key equipment to remove water, filter impurities, remove oil mist and other clean compressed air, which is the "barrier" for product quality and gas equipment. If this "barrier" fails, compressed air will be useless, or even become a "disaster". So, how can compressed air post-treatment technology or equipment take on this important task?

纵观产业实情,除水、过滤、除油等净化技术并非压缩空气行业独有,当前,压缩空气行业的除水、过滤、除油等净化技术也是在借鉴、模仿其他行业技术或基于传统技术上发展而来的。为了适应新时代高品质、低成本、低能耗的生产需求,唯有创新,尤其是不断加强与深化技术创新。

Throughout the actual situation of the industry, the purification technologies such as water removal, filtration and oil removal are not unique to the compressed air industry. At present, the purification technologies such as water removal, filtration and oil removal in the compressed air industry are also developed from the technologies of other industries or based on traditional technologies. In order to meet the production demand of high quality, low cost and low energy consumption in the new era, innovation is the only way, especially the continuous strengthening and deepening of technological innovation.

虽然,创新已成为企业与企业家的“标配口号”,那么在压缩空气后处理行业到底该如何进行技术创新呢?技术创新的路径又是怎么样呢?从哪些方面或角度进行开展技术创新呢?技术创新的路径必须着眼于解决行业痛点、满足客户需求、引领未来发展。我们以冷干机为例进行简要分析:

Although innovation has become the "standard slogan" of enterprises and entrepreneurs, how to carry out technological innovation in the compressed air after-treatment industry? What is the path of technological innovation? From what aspects or angles to carry out technological innovation? The path of technological innovation must focus on solving industry pain points, meeting customer needs and leading future development. We take the cold dryer as an example for brief analysis

从原理角度来看,当前冷冻式干燥机(冷干机)是通过冷媒制冷技术,使压缩空气中的水蒸气凝结成液滴通过自动排水阀排出,从而达到减少含水量的目的。

From the principle point of view, the current freeze dryer (cold dryer) is through the refrigerant refrigeration technology, so that the water vapor in the compressed air condenses into droplets and is discharged through the automatic drain valve, so as to achieve the purpose of reducing the water content.

冷干机运行时,对环境温度较为敏感,进气温度每升高5℃,制冷效率就要下降30%,供气露点将显著升高。一般在超过38℃和低于0℃时,就无法有效运转。

When the temperature of the inlet air increases by 5%, the air supply efficiency decreases significantly. Generally, when the temperature is higher than 38 ℃ and lower than 0 ℃, it can not operate effectively.

由于冷冻式干燥机采用的是制冷技术,所以冷媒蒸发温度不允许低于2℃,否则会结冰而堵塞管道,导致压缩空气无法通过。那么,我们是否可以通过技术创新来拓宽冷干机适应环境温度范围呢?答案是肯定的。

Because the refrigeration technology is used in the freeze dryer, the refrigerant evaporation temperature is not allowed to be lower than 2 ℃, otherwise it will freeze and block the pipeline, resulting in the compressed air can not pass through. So, can we broaden the range of the cold dryer to adapt to the ambient temperature through technological innovation? The answer is yes.

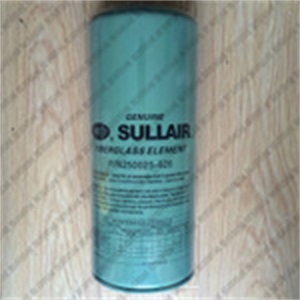

空压机精密过滤器主要应用于压缩空气净化、除杂,将混合于压缩空气中的尘埃、水蒸气、磨损粒子、油污以及细菌进行过滤。如果过滤效果不佳,由尘埃、油和水混合在一起而形成了一种极其有害的腐蚀性油泥,会快速磨损气动设备、堵塞阀门、腐蚀管路,从而造成空气泄露、工具和设备损坏、生产停滞、维修成本增加、产品报废、健康和安全受到威胁、工作环境受到影响。

The air compressor precision filter is mainly used in the purification and impurity removal of compressed air, filtering the dust, water vapor, wear particles, oil and bacteria mixed in the compressed air. If the filtering effect is not good, a kind of extremely harmful corrosive sludge is formed by the mixture of dust, oil and water, which will quickly wear the pneumatic equipment, block the valve and corrode the pipeline, resulting in air leakage, tool and equipment damage, production stagnation, increased maintenance costs, product scrap, health and safety threats, and impact on the working environment.

上一篇:螺杆式风机工作原理及特点

下一篇:影响干燥机效果的因素及设备特点

鲁公网安备 37010402001146号

鲁公网安备 37010402001146号