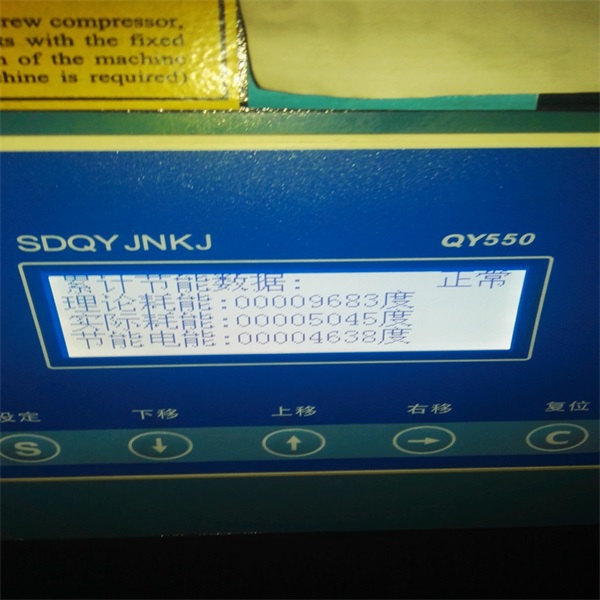

山东清越节能科技有限公司

Shandong clear energy technology Co. Ltd.

国内环保设备品牌

节能设备专家,拥有多项国家专利

全国服务热线:

0531-55555478

如何增加制氮机的使用时间?

一,制氮机,氮气入口阀门和取样阀关闭,然后关闭氮气制造机的电源开关。等待系统和管网压力的完全结束(废气从系统中富氧,注意消防安全,室内空气流通,打开)。调整采样氧气分析仪和减压阀压力调整到1.0条,调整采样流量计,气体将被分派到各地的1,注意采样量不宜过大。开始测试氮气纯度。

1、 Close the nitrogen inlet valve and sampling valve of nitrogen generator, and then turn off the power switch of nitrogen generator. Wait for the complete end of the system and pipe network pressure (exhaust gas enriched from the system, pay attention to fire safety, indoor air circulation, open). Adjust the pressure of sampling oxygen analyzer and pressure reducing valve to 1.0, adjust the sampling flowmeter, and the gas will be distributed to 1 in different places. Pay attention to the sampling quantity should not be too large. Start testing nitrogen purity.

二,在压缩空气源压力达到大于0.7兆帕,总进口截止阀,打开氮气制造机,调整减压阀将减少到约0.4至0.5兆帕的压力,同时观察吸附罐压力的情况和是否能正常气动阀的工作。

2、 When the pressure of compressed air source reaches more than 0.7 MPa, the total inlet stop valve, open the nitrogen manufacturing machine, adjust the pressure reducing valve to reduce the pressure to about 0.4-0.5 MPa, and observe the pressure of adsorption tank and whether the pneumatic valve can work normally.

三,然后顺时针打开电控氮机电源开关的PLC主站系统。两个吸附塔压力变化观察,确定两个吸附塔是否正常开关。再生器的压力为零时,一半的塔压力应接近原始工作甚至是两个塔压力。

3、 Then turn on the PLC master station system of the electric control nitrogen machine power switch clockwise. Observe the pressure change of two adsorption towers to determine whether the two adsorption towers are normally opened and closed. When the pressure of regenerator is zero, half of the tower pressure should be close to the original working pressure or even the pressure of two towers.

四,打开氧仪,电源开关,调节采样流量适量,观察氧含量。根据氮气纯度调节阀开口的需要,合格纯度自动切换成氮气贮罐,存储氮气压力氮气贮罐一般为0.6 0.8兆帕。

4、 Turn on the oxygen meter and power switch, adjust the sampling flow and observe the oxygen content. According to the need of opening the nitrogen purity regulating valve, the qualified purity is automatically switched to the nitrogen storage tank, and the nitrogen storage pressure is generally 0.60.8 MPa.

五,关闭整个系统和系统,在制氮机吸附罐压力每部分为0.6兆帕,观察制氮系统工作正常。

5、 Shut down the whole system and the system. When the pressure of each part of adsorption tank of nitrogen generator is 0.6 MPa, observe that the nitrogen generation system works normally.

六,慢慢打开空条目截止阀,流量调节至1/2的(医院中央氧气供应系统)的额定流量。调节氮气入口阀门开度来调节纯度和流量的氮气速率。

6、 Slowly open the empty entry stop valve and adjust the flow rate to 1 / 2 of the rated flow of the central oxygen supply system of the hospital. Adjust the opening of nitrogen inlet valve to adjust the nitrogen rate of purity and flow.

七,观察氧米表示的氧含量是在符合要求。当氮气纯度达到,然后慢慢打开纯天然气出口截止阀,流量设定所需的流量,关闭空条目截止阀,当设备即可投入使用后正常运行。

7、 Observe the oxygen content indicated by the oxygen meter is in compliance with the requirements. When the purity of nitrogen reaches, slowly open the outlet stop valve of pure natural gas, set the required flow rate, and close the air entry stop valve. When the equipment can be put into use, it will run normally.

上一篇:空压机噪声的控制方法

下一篇:制氮机的氮气干燥度受到哪些因素影响?

鲁公网安备 37010402001146号

鲁公网安备 37010402001146号